Guangdong Tongxing Hi-Tech Intelligent Equipment Co., Ltd.

Address: No. 2, Zone 1, Xiakeng Village, Tongde Community, Baolong Street, Longgang District, Shenzhen

Tel: +86-0755-89715588

Mail: txgk@sztxgk.com

Excellent supplier of automation equipment

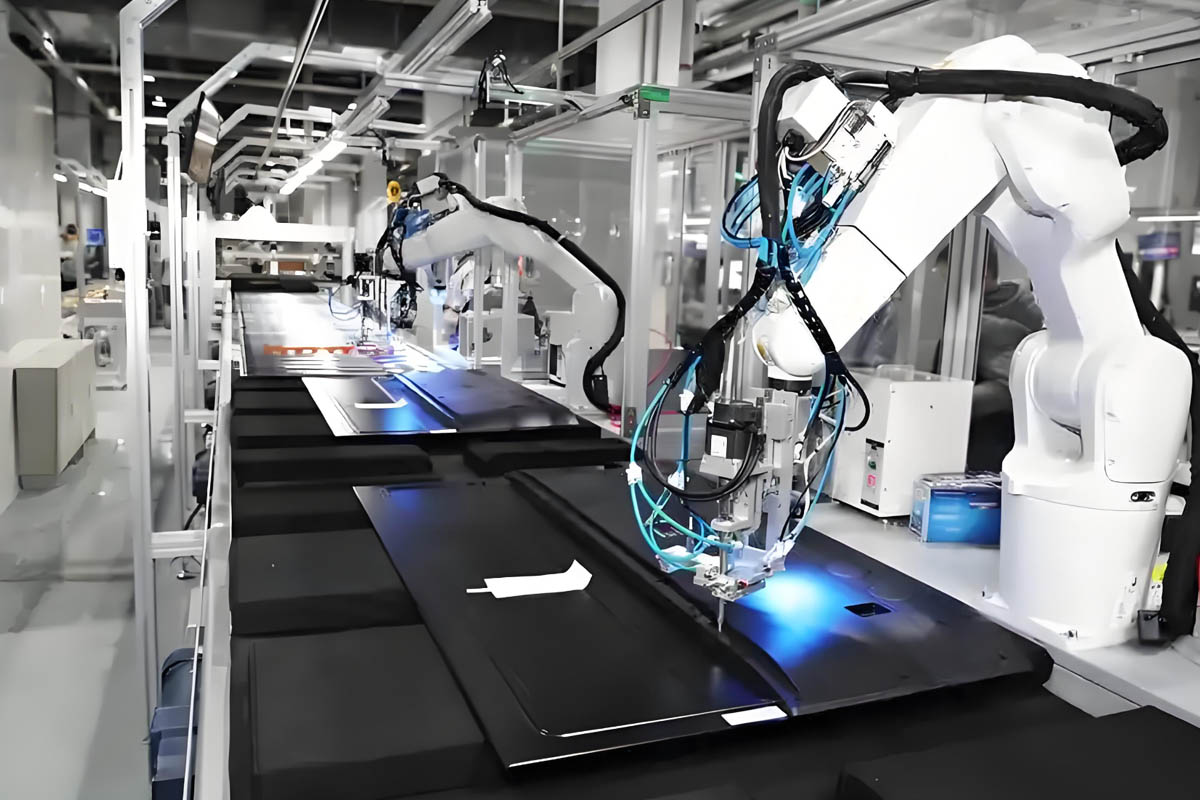

As a leading domestic whole-plant solution provider, we have established long-term cooperative relationships with many domestic listed companies and large enterprises since our establishment. Changhong, Skyworth, TCL, ZTE, Midea, Kangguan, Gree, HKC, Oma, etc. are all our automation partners. From research, planning, design, manufacturing, installation, deployment and service, we provide one-stop solutions and services throughout the process.

Started in 1998, with more than 20 years of experience in manufacturing automation equipment. The equipment has a high degree of automation, which can save manpower, time and energy, reduce labor intensity, adapt to extreme environments such as freezing, refrigeration, and high temperature, effectively shorten the investment return cycle, and significantly improve the overall competitiveness of the enterprise.